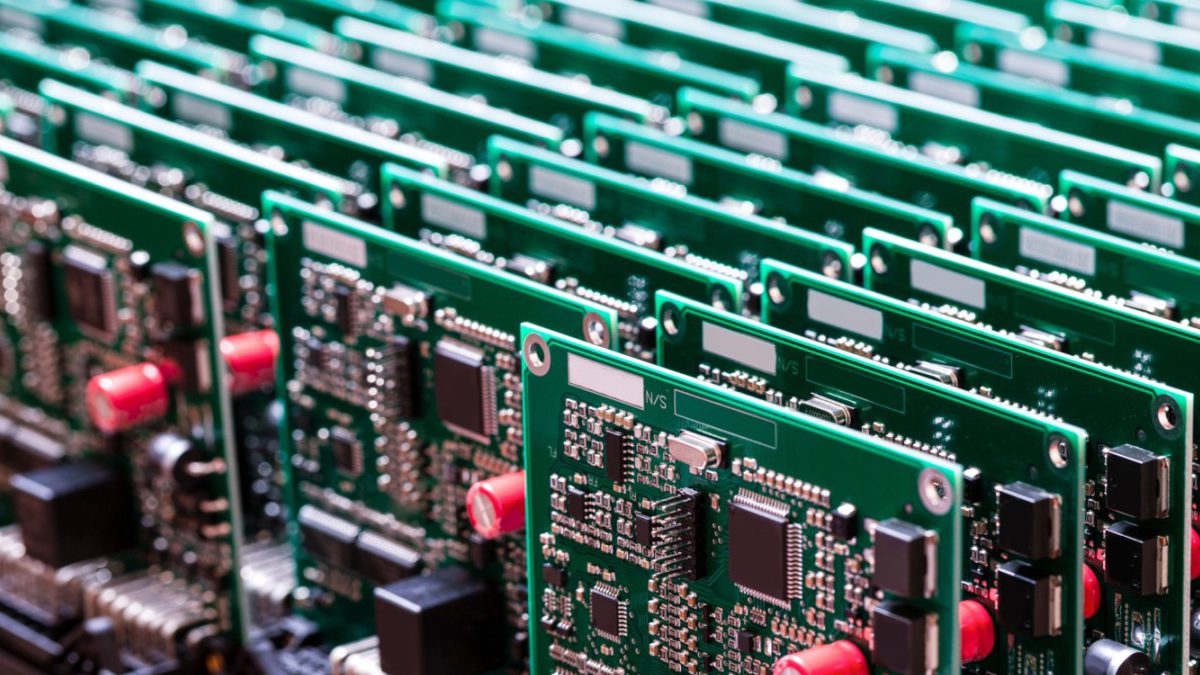

In the quickly transforming sector of electronics and technology, the call for customized, personalized, and specialized devices has spurred a rise in the manufacturing of low volume printed circuit boards (PCBs). PCB assembly plays the role of spine in the being of electronic devices and is employed to ensure the overall optimization and efficiency of devices. The electronics industry has shown continuous development over time and to reinforce this progression, a pivotal move in this direction has been facilitation of mass production of PCB boards, aligning with swift development and meeting growing demands for electronics components. However, in the face of technological evolution, the landscape of mass production has shifted towards a more refined approach of low volume PCB assembly, accentuating the importance of customization, efficiency, cost effectiveness, prototypes, pilot runs in today’s electronic environment. Low-volume PCB assembly is the process of production of PCBs on a low scale, typically ranging from 1 piece to 1500 pieces or 3000 pieces max. Below are some key reasons explaining the necessity for low volume PCB assembly.

Need for Low Volume PCB

- Prototyping and testing: Low-volume PCB allows an innovator to test PCBs before committing to large-scale production. While developing a new product or a prototype, several iterations of trying and testing of different design layouts must be accomplished in order to optimize the device and low volume PCB ensures a seamless experience. Low volume PCB assembly has the ability to swiftly develop functional prototypes for testing, debugging and feedback collection.

- Small-scale production: Start-ups or small and medium-sized companies deal with products on a lower scale without including the high cost of build-ups. Low volume PCB takes their request into consideration and align with their need for addressing specific production needs while managing the cost-effectiveness during the product introduction phase.

- Customized service: Low-volume PCB assembly offers a special and unique service to engineers and innovators that cater to their highly specific needs or appeal to a niche market by producing specialized Printed Circuit Boards (PCBs). Low volume PCB is free of constraints and scale requirements associated with mass production, making it viable and feasible for users.

- Customization and flexibility of design: Flexibility of PCB design can’t be achieved with high volume PCB assembly due to costs. In contrast, low volume PCB assembly is inclined to fulfill the demands of customizing PCB designs with ease by allowing the incorporation of unique components based on individual requirements.

- Cost-effectiveness: PCB assembly working on large scale production takes advantage of significant investments in tooling and build-ups. In comparison to high volume PCB, low-volume PCB eliminates the need of extensive build-ups for PCB assembly and reduces material waste playing a crucial role in financial benefits.

- Efficiency: The effectiveness of low volume PCB boards is multi-faceted in nature and stands out as an efficient solution across various aspects. Its efficiency is underscored by its cost-effectiveness, rapid prototyping capabilities, personalized features, and adaptability for start-ups. Collectively, these aspects solidify low-volume PCB assembly as an efficient and strategic preference for diverse industry requirements.

- Reduced risks: Working with low volume PCB leads to a dramatic decrease in the occurrence of expensive errors. Low volume PCB assembly provides an opportunity for innovators to test the board before making a commitment to on-time delivery, all without the risk of economic losses. It also allows users to experiment with different ideas and innovation ensuring that the final product closely matches with the desired effect.

- Market testing: Low volume PCB assembly is a well-thought scheme which equips companies with the capability to release new products to the market while minimizing risks associated with high volume PCB assembly. By opting for low volume PCB, companies can thoroughly test market dynamics and review customer feedback and validate the acceptance of an innovative product before undertaking large scale production of boards and enhance its features through user experience.

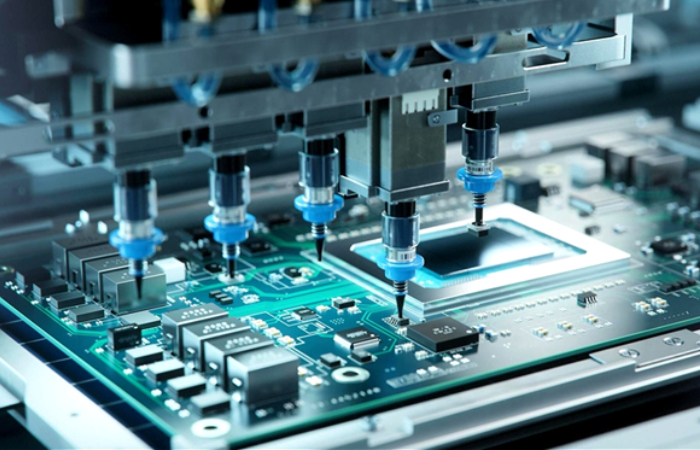

- Turnaround time: Turnaround time refers to the total time taken by manufacturers for converting initial PCB design layouts into market ready PCB boards. The time taken involves all the steps included in the manufacturing process of PCB such as designing of layout, fabrication, assembly, testing, etc. Low volume PCB have a quick turnaround time due to simplified process, reduced build-up time and flexibility in production scheduling.

Symbiotic Relationship between Affordability and Effectiveness

The symbiotic interplay between affordability and effectiveness intricately shapes electronic manufacturing in low volume PCB assembly. Based on financial considerations, affordability guarantees that the integration of low volume PCB is financially viable for a diverse set of businesses. It paves the way for expanded involvement and innovative breakthroughs within the sector. Within the sphere of low volume PCB assembly, cost-effectiveness originates from multiple elements such as alleviation of market risks, fast turnaround, minimized upfront investment, reduced material waste, low-cost prototyping and testing, flexibility for niche applications, and adaptability to incorporate changes as per market needs with minuscule losses. Conversely, the effectiveness of low volume PCB assembly lies in its proficiency to deliver optimal results through efficient processes, quick prototyping and adaptability to fulfill different project demands. The dynamic interaction between affordability and effectiveness affirms that the pros of low volume PCB assembly go beyond financial constraints to achieve efficiency and flexibility in PCB assembly. The mutual symbiosis between the two safeguards the success and sustained advancement of low volume PCB as an indispensable method of manufacturing in electronics realm.

Conclusion

Finally, there is concluding remarks. It is evident that both high-volume and low volume PCB assembly play a pivotal role in the domain of electronics. While high volume PCB assembly is inclined towards providing stable and permanent layouts for mass production whereas the role of low volume PCB has become irreplaceable owing to diverse needs in the electronics market. Low volume PCB accommodates the new innovators and promotes the engineering of electronic devices. Their cost-effectiveness and efficiency make them a significant component of any novel idea prototype where flexibility and quick turnaround are paramount. In essence, the affordability and efficiency of low volume PCB assembly contribute to the overall innovation within the industry.