Cobot Applications

One of the most vital steps in the manufacturing of a product is its final packaging. A product’s packaging must protect it from unfavourable environments, keep it safe during shipment and protect it from any damage while it’s sitting on a shelf in a store. Not just that, but the kind of packaging can determine how attractive a product looks to customers, impacting the manufacturer’s business. Being some of the most crucial operations, packaging and palletizing operations require a lot of manpower. However, the nature of these tasks is not best suited for employees due to their repetitive nature. This article will take a look at how these operations can be modified to be more comfortable for humans with the emergence of Industry 4.0 solutions.

Table of Contents

The Importance of End of Line Operations

If there’s one thing common to almost all industries, it’s the need for reliable packaging. Without it, many products will not be able to withstand harsh conditions for long, heavily impacting any manufacturer. Be it food items, daily commodities or electronic devices – every manufactured product must be secured to keep it safe as well as attract more customers. Apart from packaging, palletizing too is a crucial step for manufacturers – it ensures that your packed products are stored safely and uniformly, easing wide-spread distribution. As pallets prevent product damage, it’s important for any manufacturer to palletize their goods to increase the product life cycle.

These processes do come with certain disadvantages – the people tasked with performing these operations face severe ergonomic risks everyday due to their repetitive and strenuous nature. Packaging involves a lot of physically taxing movements, and performing them repeatedly can affect workers greatly. As production levels depend on the final packaging, it’s important for this process to be performed to the maximum potential so that manufacturers can roll out products to their full capacity. Although humans are precise, many times the required level of efficiency may not be met due to a variety of factors.

With new advancements in technology that have emerged during the current Industry 4.0, vital yet strenuous tasks like packaging and palletizing can instead be automated with the help of robots to relieve employees from their dangerous side effects as well as optimize factories by increasing efficiency and precision. Re-assigning these tasks to robots can result in employees performing more valuable work without compromising the quality of produce. However, for many manufacturers in India, automating their factories is more of a hassle than it is advantageous.

Traditional robots are cumbersome to deploy for many Indian manufacturers. These robots are not safe to work around and pose risks for hazards and accidents. Many employees find it difficult to learn how to operate them quickly and efficiently, causing a demand for highly skilled labour, something that is unpredictable due to fluctuating labour supplies. These robots utilize very high-power supplies, are difficult to program and operate and use up too much of the shop floor due to their need of protective fencing around them. However, Industry 4.0 has led to the emergence of the perfect solution for this – Human Robot Collaboration.

Automating Packaging & Palletizing

Human Robot Collaboration (HRC) has been one of the most useful solutions to come out of the current industrial revolution – more specifically, Collaborative Robots, or cobots. Built on the concept that humans and robots can work together in the same environment, cobots are the perfect solution that manufacturers need to optimize their shop floors. Cobots have become the fastest growing market at around 45% CAGR – with a wide variety of applications, industries from almost every sector have adopted them in their factories. For many manufacturers, automating packaging and palletizing applications using cobots has been essential in skyrocketing their production levels while eradicating the ergonomic risks that employees who work in these jobs face everyday.

Unlike traditional robots, cobots do not require any protective fencing around them (subject to application risk assessment) as they are programmed to work safely around humans. Thus, collaborative robots do not act as a replacement for humans but instead as an automated assistant, allowing the human to continue their work with more ease. This acts as a great advantage, especially for SMEs as they do not have to sacrifice their shop floor to accommodate the cobots. This combined with their easy programming and low power consumption has made cobots the go-to solution for manufacturers in almost all industries.

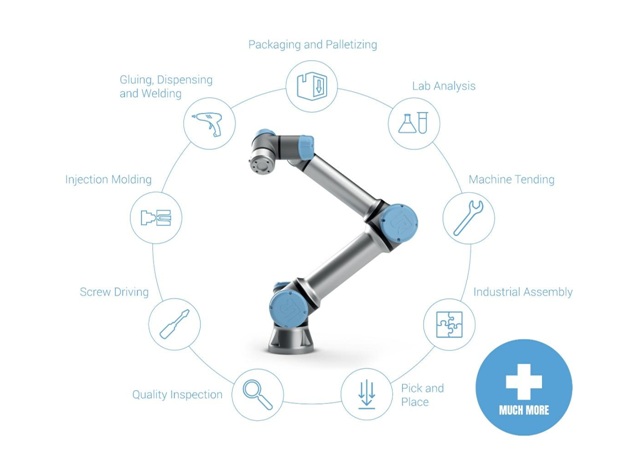

Cobots can perform a multitude of applications, from assembly operations like screw driving to finishing techniques like polishing or spray painting. Due to the safety features that they are programmed with, all of these applications can be performed without the need of any protective fencing, around the clock. Their ease of operation lets employees learn how to use them within a day, upskilling labour in the process.

India’s FMCG industry

Today, the retail and FMCG sectors are some of South Asia’s largest & fastest-growing industries, staying strong and rising steadily even amidst the pandemic. India’s retail industry alone is expected to reach US$1.1 trillion by the end of 2020. Employees in the FMCG industry are subject to many strenuous and repetitive tasks, many of which are due to the labour-intensive activities that manufacturing in this industry requires. Operations such as packaging and palletizing pose massive ergonomic risks to a company’s employees, bringing upon both physical and mental stress. Being heavily dependent on seasonal demands and changing consumer tastes, manufacturers in the FMCG industry must continue to roll out high produce throughout the year without sacrificing their quality. With their efficiency, flexibility and safety, collaborative robots have become an easy answer for FMCG manufacturers, especially for repetitive tasks that require little skill such as end of line packaging and palletizing. With cobots, tasks such as picking and placing packets, packaging them in boxes and palletizing the packed boxes can now be reassigned, enabling employees to focus on tasks that require more skill and ensure that all talent is being utilized.

In India itself, many companies in the FMCG industry have switched to an automated form of manufacturing in recent years. One of the largest cosmetics companies, L’Oréal India has deployed cobots at their factory in Pune for palletizing. The end-of-the-line operations posed severe ergonomic risks to workers at L’Oréal India’s plant in Pune, where a single operator would handle 8,500 kilograms per shift while manually palletizing. L’Oréal’s mission to create a safer work environment led them to deploy cobots that are used for automatic palletization, completely eradicating the ergonomic risk to staff. The zero-maintenance cost and easy programming also made cobots the ideal robot choice for the company, as well as the flexible redeployment, which has enabled the L’Oréal team to independently move and use the cobot on different lines.

HRC – Empowering all Industries

Collaborative robots can be used for packaging applications in other industries as well. Multinational technology manufacturer Dell installed cobots at their factory in Chennai – one of Dell’s only ten manufacturing plants in the world. The delicate nature of their products meant that the tech giant had to be careful in automating their lines in order to avoid any mishaps. Dell thus opted to deploy a cobot for their end-of-line packaging, skyrocketing their production levels. By being able to handle delicate products without posing any risk, cobots became the perfect automation solution for Dell.

The use of Human Robot Collaboration has played a vital role in helping manufacturing companies in India optimize their production while increasing quality and safety. Being some of the most crucial operations in manufacturing, packaging of products and their palletization requires employees to be active at all times, but their repetitive nature puts a severe strain on them. Many companies in India such as L’Oréal and Dell have taken a step towards Industry 4.0 by automating their factories and making them future-proof. As more and more manufacturers are becoming aware about its benefits, with time India can completely adapt to collaborative technology and use it to perform repetitive but vital tasks, thus empowering not just their employees, but the entire manufacturing landscape.