Table of Contents

Capacitor Definition

A capacitor is a device used in Vemeko Electronics to store and discharge electrical energy. It is composed of two conductive plates that are separated by an insulating material known as a dielectric. When a voltage is applied to the plates, it generates an electric field, resulting in the accumulation of a positive charge on one plate and a negative charge on the other plate. The capacitor retains this charge, and its ability to store charge is determined by its capacitance value, which is measured in farads (F).

Vemeko is a seasoned distributor of electrical components including Zynq-7000 SoC, FPGA Spartan-7, Artix-7 FPGA, Virtex-7 FPGAs, Kintex-7 FPGAs, Virtex-6 FPGA, Spartan 6 FPGAs, MAX II CPLDS, Cyclone V FPGA, and Cyclone III FPGAs.

What are Ceramic Capacitors?

Ceramic capacitors are a type of capacitor that utilizes a ceramic substance as the dielectric, which acts as an insulating material between the two conductive plates of the capacitor. These capacitors are extensively employed in electronic circuits owing to their small dimensions, substantial capacitance values, and commendable electrical efficiency.

Characteristics of Ceramic Capacitors

Dielectric Material: Ceramic capacitors utilize different ceramic materials as the dielectric, such as ceramic compounds like barium titanate or titanium dioxide. These materials provide high dielectric constants, enabling relatively high capacitance values in compact physical sizes.

Capacitance Range: Ceramic capacitors are available in a broad range of capacitance values, from picofarads (pF) to microfarads (μF) and beyond. They can offer high capacitance values even in small package sizes, making them suitable for compact electronic devices.

Voltage Ratings: Ceramic capacitors are accompanied by various voltage ratings, indicating the maximum voltage they can withstand without the risk of failure. It is crucial to select a capacitor with a voltage rating higher than the expected voltage in the circuit to prevent breakdown or damage.

Temperature Stability: Ceramic capacitors demonstrate good temperature stability compared to some other types of capacitors. However, their capacitance value may vary with temperature, which is specified by the capacitor manufacturer in terms of temperature coefficient.

Capacitor Classes: Ceramic capacitors are classified into different classes based on their temperature coefficient and stability. The most common classes are Class 1 and Class 2. Class 1 capacitors possess a low-temperature coefficient and high stability, although they generally have lower capacitance values. On the other hand, Class 2 capacitors have a higher temperature coefficient and are available in higher capacitance values.

Surface Mount Technology (SMT): Ceramic capacitors are widely available in surface-mount packages, which are suitable for automated assembly processes utilized in modern electronics manufacturing. Due to their small size, reliability, and cost-effectiveness, they have become a popular choice for SMT applications.

Ceramic capacitors find extensive applications, including decoupling and bypassing in power supply circuits, filtering, timing, coupling, and voltage regulation in electronic devices and systems.

Are Ceramic Capacitors Polarized?

Ceramic capacitors are typically non-polarized, meaning they can be connected to a circuit without considering the voltage polarity. Unlike electrolytic capacitors, which have positive and negative terminals, ceramic capacitors do not require polarity markings.

The non-polarized nature of ceramic capacitors makes them versatile and easy to install in circuits without worrying about their orientation. However, it is worth noting that there are specialized ceramic capacitors, like tantalum ceramic capacitors, that can be polarized and have specific polarity markings. These polarized ceramic capacitors are less common and are typically used in specific applications where polarity is important.

In general, when using standard ceramic capacitors, you can connect them to a circuit in any orientation, and they will function correctly regardless of the voltage direction.

Multilayer Ceramic Capacitor

A multilayer ceramic capacitor (MLCC) is a ceramic capacitor that is composed of multiple layers of ceramic material with metal electrodes in between. This construction allows for the achievement of high capacitance values in a compact size. MLCCs possess precise tolerances and accuracy, making them suitable for applications that require high stability and low loss. They provide accurate results and maintain stable capacitance values even when subjected to varying voltage, frequency, and temperature. Additionally, MLCCs offer the benefit of small size, making them advantageous in situations where high component packing densities are necessary. Furthermore, these capacitors are designed to withstand high voltages and are referred to as power ceramic capacitors. They are larger in size compared to PCBs and feature specialized connections for safe connection to high-voltage supplies.

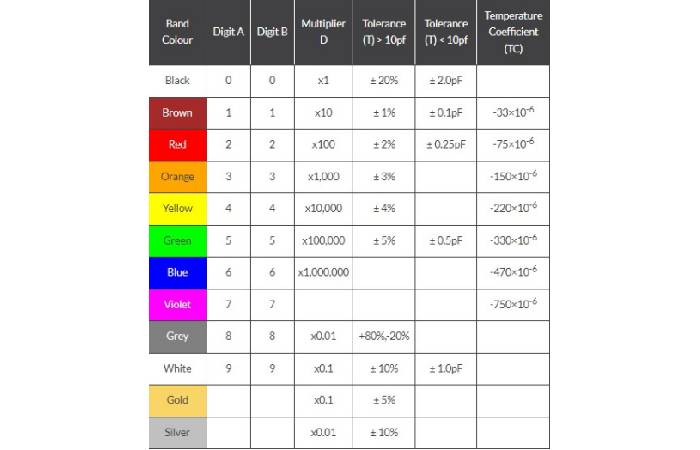

Capacitor Color Code

How to Read A Ceramic Capacitor Value?

Ceramic capacitors are commonly marked with alphanumeric codes on their bodies to indicate their capacitance value, voltage rating, tolerance, and other specifications. To read the value of a ceramic capacitor, refer to the following general guide:

Capacitance values are typically indicated by a three-digit or four-digit code. There are two common coding schemes used for this purpose.

In the three-digit code scheme, the first two digits represent the significant figures, while the third digit indicates the number of zeros to add. For instance, if we have a code of 104, the “10” represents 10, and the “4” signifies four zeros. Therefore, the capacitance value would be 100,000 pF or 100 nF.

On the other hand, the four-digit code scheme uses the first three digits to represent the significant figures, and the last digit serves as the multiplier. The multiplier indicates the number of zeros to add. For example, if we have a code of 473K, the “473” represents 47, and the “K” indicates three zeros. Thus, the capacitance value would be 47,000 pF or 47 nF.

The unit of measurement for capacitance values is typically indicated by a letter or symbol. Common units include pF (picofarads), nF (nanofarads), and μF (microfarads). The unit may be explicitly mentioned or represented by an abbreviation.

It is also important to check for the voltage rating of the capacitor. The maximum voltage that the capacitor can handle is often mentioned alongside the capacitance value. This may be indicated as WV (working voltage), VDC (direct current voltage), or simply V. For example, if the voltage rating is mentioned as 50V, it means that the capacitor can handle a maximum voltage of 50 volts.

Lastly, the tolerance represents the acceptable deviation from the specified capacitance value and is often indicated as a percentage. Common tolerance values include ±5%, ±10%, ±20%, and so on. For instance, if the tolerance is mentioned as ±10%, it means that the actual capacitance can vary by ±10% from the indicated value.

What is A Ceramic Capacitor Used for?

Ceramic capacitors are widely used in electronic circuits due to their favorable electrical properties and small size. They serve various purposes in electronic applications:

1. Decoupling and Bypassing: Ceramic capacitors are commonly utilized in power supply circuits to reduce noise and voltage fluctuations by creating a low-impedance path for high-frequency noise to bypass the power supply lines.

2. Filtering: They are employed to eliminate unwanted noise or high-frequency signals from a circuit, shaping the frequency response in low-pass, high-pass, or band-pass filter configurations.

3. Timing and Oscillators: Ceramic capacitors are often used in timing circuits and oscillators to control signal frequency and duration, working in conjunction with resistors and inductors to create precise timing components.

4. Coupling and DC Blocking: They are used to couple or block direct current (DC) while allowing alternating current (AC) signals to pass through a circuit, facilitating the transfer of AC signals between different stages of an amplifier or audio system.

5. Voltage Regulation: Ceramic capacitors stabilize and smooth out voltage fluctuations in voltage regulation circuits, suppressing high-frequency noise and providing transient response to maintain a steady voltage level.

6. Snubber Circuits: They are employed in snubber circuits to dampen or suppress voltage spikes and transient voltage pulses generated by inductive loads, protecting sensitive components from voltage surges.

7. RF Applications: Ceramic capacitors are extensively used in radio frequency (RF) circuits and wireless communication devices for impedance matching, tuning, and resonant circuits.

8. Sensor Applications: They play a vital role in signal conditioning and filtering in various sensor applications, including temperature, pressure, and humidity sensors.

9. General Electronics: Ceramic capacitors are found in a wide range of electronic devices, such as computers, smartphones, televisions, audio equipment, and automotive electronics, serving various functions in power supply circuits, signal processing circuits, and timing circuits.

Due to their versatility and wide range of capacitance values, ceramic capacitors are widely employed in numerous electronic circuits and systems, providing essential functions such as energy storage, signal conditioning, filtering, and timing.

Conclusion

To summarize, ceramic capacitors are extensively utilized in electronic circuits because of their notable attributes such as high capacitance, affordability, and compactness. They exhibit exceptional stability, reliability, and minimal losses, rendering them suitable for various purposes like decoupling, filtering, and timing. The properties of ceramic capacitors differ based on the specific ceramic material employed, thus it is crucial to select the appropriate type for each application. All in all, ceramic capacitors are indispensable components in contemporary electronics and will persistently contribute to the advancement of emerging technologies.