Interactive Mass Customisation

Back in the time when Ford T was launched, we were all up for it in the same black colour. We would still be up for it, if it would have come in any other colour than black. Nowadays, we have a habit of using identical phones, computers, and even to the extent of buying the same kind of shoes.

In a world, which is swamped by goods that are perfectly alike, we all have a desire to stand out and show off with unique possessions. Thus, today’s consumers, have different preferences and views compared to the previous generation.

The expectations and preferences of these customers have been fuelled through the interactions with the digital world. And that is why consumers now are not ready to settle for the same thing, which their friends or relatives have already possessed or used.

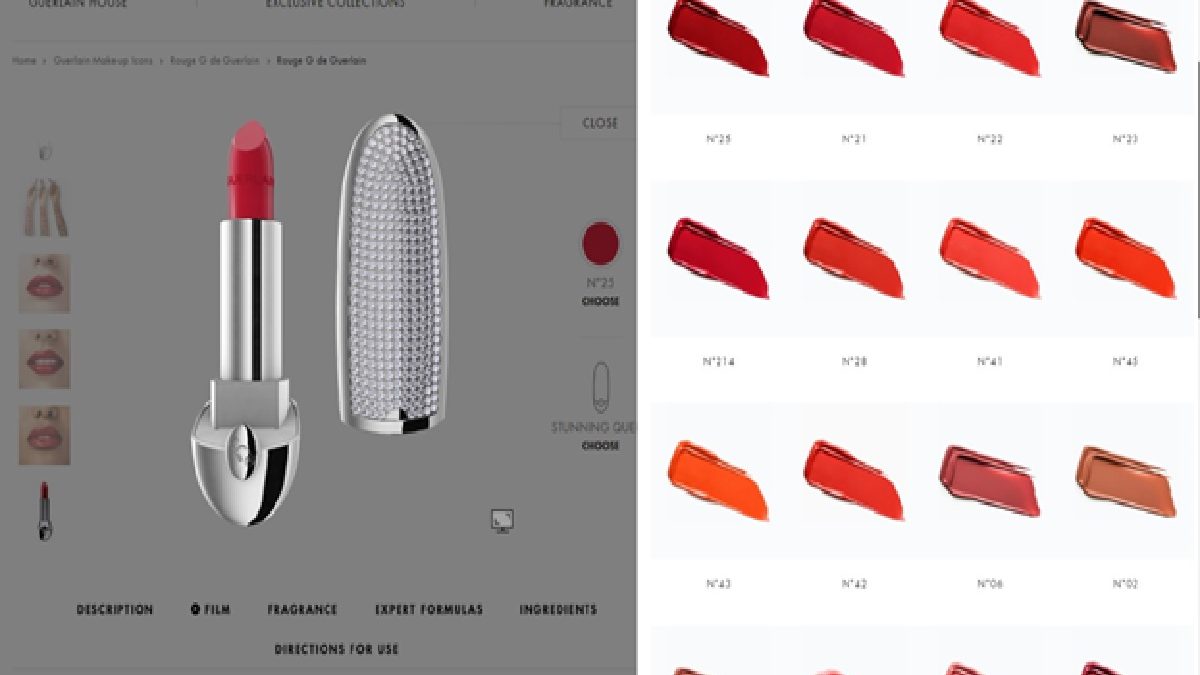

Now the demand for something that is one of a kind has increased. And to satisfy this demand, marketers, industries and even luxury brands are integrating Customisation features into their products to match the unique interest and habits of their target market while providing them with the opportunity to showcase their individuality by owning the product. And this is exactly where mass colour comes into play.

Table of Contents

What is Mass Customisation?

Marketers refer to Mass Customisation as a marketing business method that is an ideal blend of flexibility and personalization of products. Which are custom made, along with low unit costs for being associated with mass production (Sai, 2019).

In other words, businesses have started to adopt this in an attempt to give customers what they want, while still making a profit.

This has made mass customisation a new wave of innovative technology in designing product strategies. With increasing sales through mass customisation, several numbers of brands over the period have taken a shot at this innovative technology, but have been disappointed due to lack of knowledge regarding the right implementation of mass Customisation (Zeijderveld, 2018).

Many marketers and brands have frequently been accustomed to failure as they are observed to cloud the lines between mass production and mass customisation (Kubs, 2018).

In order to keep up with the market, it is vital to comprehend that customisation implies to produce according to consumer needs, however, production means to simply produce goods based on a single standard (Sai, 2019).

Following this, mass customisation is producing goods to suit the needs of customers, on a large scale. On the other hand, mass production means to produce a single standard product on a large scale.

Surprisingly, the pioneering and marketing tactic of customisation originates from a period of historical times when the system of factories was non-existent. For instance, a cobbler provided services of designing shoes, custom-made, i.e. according to the customer’s foot size and preferences, when there were no shoemaking companies.

Nevertheless, owing to the absence of factories and technological advancement, such customisation was not done on a large scale (Zortax, 2017).

Existing Wave of Mass Customisation in Luxury Brands

In contrast to the older times, modern era’s computer and IT-based technologies have made the emergence of mass customisation possible even in the luxury brands of not just cars, but footwear, clothes, watches and accessories.

Illustrating an example from the German automaker, also known as a premium brand, Volkswagen. It has been confirmed as an early bird to provide mass customisation through new 3D technologies (Jackson, 2018).

The head of their technical and innovation department presents his stance in favour of mass customisation, explaining that automation in the production process is meeting new challenges of changing trends every day.

Customers are demanding more personalized features, simultaneously the complexity of engineering new models is increasing. For that reason, the company has now taken the approach of state-of-the-art technologies (i.e., 3D printing) to ensure a personalised, smooth and efficient product at the end of the finishing line.

Other brands being a proponent of mass customisation include Nike and Vans (Garoia, 2018). Adopting the feature of mass customisation in their product line have enabled their consumers to select from a range of various materials and combination or themes of colours to design their sneaker according to their preference.

While, a women’s footwear brand, known with the name of Shoes of Prey. It offers plenty of personalization features to choose from. Such as the height of heels, style, leathers used, and fabric used in the shoes.

Which Technology suits best for Mass Customisation?

In spite of all the options and demands, customers seek to satisfy through custom-made products. They are reluctant to spend a high percentage of their income on it when it comes to the comparison with a non-customized version of those custom-made products. It happens since customization is perceived to be something of a premium feature, adding value to a product, hence, in general, is expensive.

- But the upcoming brands have made mass customisation cost-effective with the assistance of tools associated with additive manufacturing. Such as 3D printing and augmented reality technology.

- 3D printing prevents excess cost, and help to achieve cost-savings in every stage of manufacturing, ranging from capital purchase to minimizing tooling costs and labour productivity expenses (Recrosio, 2017). Along with all this, the manufacturer also benefits from the competitive advantage it potentially provides.

- It operates through taking numerous design alterations, frequent number of times, and prototypes before the product are prepared to be delivered to the end-user.

- Another area where 3D printing is seen as a cost-saving tool is inventory and supply chain costs. This can be explained through the process of manufacturing in Mass Customisation. Wherein, the process entails a diverse set of raw materials.

- Through 3D printing, the manufacturers gain the ability to print parts on-demand. Thus, managing the costs of inventory, storage, and distribution by a greater level (LaSelle, 2019).

The buyers of the modern era give significance to customisation. Where even their phones can be personalized by downloading various combination of apps, their device and google accounts. Know all about their preferences while giving them nonstop access to their favourite movies, books and music (Zortax, 2017). Hence mass customisation is the only way forward!

References

- Garcia, K. (2018). Fashion Is Popular for Mass Customization. Retrieved from https://www.emarketer.com/content/fashion-is-popular-for-mass-customization

- Jackson, B. (2018). Volkswagen Moves to Mass Customization, Aims for Over 100,000 3d Printed Units Per Year. Retrieved from https://3dprintingindustry.com/news/volkswagen-moves-to-mass-customization-aims-for-over-100000-3d-printed-units-per-year-139604/

- Kubs. (2018). 3D Printed Sneakers and Mass Customization – Is Adidas There Yet? Retrieved from https://digital.hbs.edu/platform-rctom/submission/3d-printed-sneakers-and-mass-customization-is-adidas-there-yet/

- LaSelle, R. (2019). Meeting Mass Customization Demands with 3D Printing. Retrieved from https://www.jabil.com/insights/blog-main/meeting-mass-customization-demands-with-3d-printing.html

- Recrosio, E (2017). Benefits of 3D Printing: Mass Customization. Retrieved from https://www.sculpteo.com/blog/2017/01/11/benefits-of-3d-printing-mass-customization/

- Sai, S. (2019). Difference between Concepts of Mass Production and Mass Customization | Plant Layout. Retrieved from http://www.yourarticlelibrary.com/business/plant-layout-business/difference-between-concepts-of-mass-production-and-mass-customization-plant-layout/69516

- Zeijderveld, J. (2018). Mass Customization In 3D printing: The Best Projects! Retrieved from https://www.sculpteo.com/blog/2018/04/18/mass-customization-in-3d-printing-the-best-projects/

- Zortrax. (2017). Mass Customization Trend: Design Your Own Reality with 3D Printer. Retrieved from https://zortrax.com/blog/mass-customization-trend-design-reality-3d-printer/

Bio

Yahong Zhang is head of marketing at Hapticmedia, a provider of 3D configurators that improved customer journey and have doubled clients’ e-commerce conversion rates. She also writes about SEO and inbound marketing for start-ups.