Beam shaping with DOEs

Diffractive Optical Elements (DOE), also known as computer generated holograms (CGH), are optical components that exploit the wave nature of light to shape it. They can be designed to perform complex transformations on monochromatic light beams like laser beams, coherent or incoherent alike.

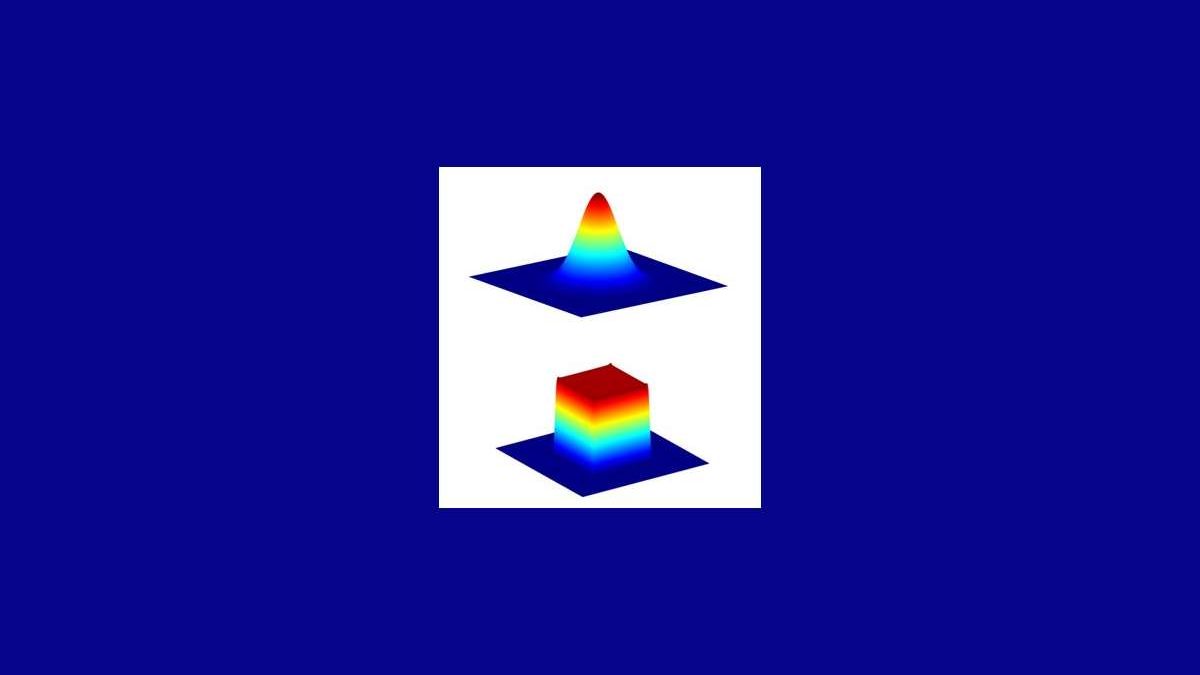

One relevant application is beam shaping in which the intensity distribution of a light field can be optimised according to some target profile. The most widespread application of beam shapers is transforming a Gaussian laser beam into a Top Hat profile laser beam. This specific transformation consists of turning the Gaussian beam, with it’s large transfer region having slowly decaying edges characteristic of an apodised laser beam, into a uniform intensity distribution with very sharp edges and very small transfer region. This transformation means that irrespective of laser pulse energy, the area above a certain process threshold remains the same, unlike in a gaussian beam where the spot width is directly correlated to the pulse energy, i.e with increasing energy the spot grows in size.

Applications of Top Hat laser beams

This type of beam irradiance profile is harnessed in many industry sectors where high quality coherent laser beams need to be focused into an area of precise shape and size. In fact, the irradiance of the Top Hat laser beam can be arranged into many different distributions by a properly designed DOE, including round, square, rectangle, line and even exotic structures such as several rectangles or lines with well defined spacing. The intensity distribution will depend on the application in mind.

Among the different applications for Top Hat laser beams we can cite the following:

- Laser micromachining- ablation, kerf removal, micro-drilling

- Laser scribing – electrodes, dias etc

- Laser cutting

- Lithography

- Annealing and surface treatments

- Microscopy & Lightsheet Cytometry

- Metrology of semiconductor wafers,

and many others.

Each application will demand its own type of Top Hat laser beam. For instance, in hole drilling the Top Hat beam can be square or circular whereas some applications in materials processing will benefit from a line or square profile distribution. In cytometry, a Top Hat beam ensures that each cell being monitored is illuminated with the same irradiance.

All these applications share a common objective which is to maintain a sharp border between treated areas and non-treated areas, allowing for the treated area to remain mostly unchanged even when the laser energy is changed, and utilizing almost the entire energy of the beam for the process. This is not achievable in a gaussian beam, where a large percentage of the energy is wasted – either by being below the process threshold, or by being unnecessarily higher above it.

Typical setup for a Top Hat beam shaper

The most common optical setup where a beam shape is used is a laser beam that illuminates the DOE, followed by a focusing lens (or lens system). This lens can be placed anywhere after the DOE, and the far field of the DOE is reproduced at the focal plane of the lens.

For best performance of the beam shaper, the Top hat beam shaper clear aperture and all other optics along the path must be at least twice the input laser beam diameter. The lens and other optics such as folding mirrors must provide diffraction limited and field-corrected performance. Still, a Top Hat laser beam shaper can be integrated into very small laser processing systems, as well as scanning F-theta+ glavo setups, given the correct design.